Article of the Month -

September 2008

|

Review of Standards, Best Practice, Testing

and Calibration in Global Navigation Satellite System (GNSS)

Mr. David MARTIN, France

This article in .pdf-format (7

pages and 367 kB)

This article in .pdf-format (7

pages and 367 kB)

1) This paper has been prepared for

and presented at the FIG Working Week in Stockholm, Sweden 14-19 June

2008.

Key words: GNSS, standards, best practice, calibration.

SUMMARY

Surveyors as professionals must fulfil certain legal, regulatory

and/or accuracy requirements for their clients. Typically they will

strive to do this in an optimal cost effective way and with the most

appropriate equipment for the job at hand. Naturally it requires a good

understanding and assurance in the instrumentation employed. Clients

want the most from what they pay for. Legislative authorities as well as

private and public companies require confidence that the services

rendered are in conformity with globally accepted best practice rules.

Generally this involves the application of internationally recognized

standards.

Considerable efforts have been made concerning testing in the field

of surveying. In particular the ISO standard 17123 parts 1 through 8

concerning levels, theodolites, EDM’s, total stations and most recently

GNSS field measurement systems in real time kinematic (RTK); have been

published. Instrument manufacturers often quote these standards when

making reference to their instruments precision. Each of the ISO 17123

standards prescribes test procedures aimed at determining if the

instrument is functioning correctly and qualifying its precision and

performance.

This paper provides a general overview of standards, best practice,

testing and calibration related to GNSS.

1. INTRODUCTION

Surveyors as professionals must fulfil certain legal, regulatory

and/or accuracy requirements for their clients. Typically they will

strive to do this in an optimal cost effective way and with the most

appropriate equipment for the job at hand. Naturally it requires a good

understanding and assurance in the instrumentation employed.

Clients want the most from what they pay for. Legislative authorities

as well as private and public companies require confidence that the

services rendered are in conformity with globally accepted best practice

rules. Generally this involves the application of internationally

recognized standards.

Best practice is a management idea which asserts that there is a

technique or method that is more effective and efficient at delivering a

particular outcome than any other. It maintains that with proper

processes, checks, and testing, a desired outcome can be delivered with

fewer problems and unforeseen complications. Best practice is generally

based on repeatable procedures that have proven themselves over time for

large numbers of people. The notion of best practice does not commit

people or companies to one inflexible, unchanging practice. Instead, it

is an approach that encourages continuous learning and improvement. Best

practice in a field can be expected to evolve as new information,

instrumentation and methodology becomes available.

Best practice in surveying and GNSS in particular may have some very

job specific aspects associated with it. There may be legal and/or

legislative imperatives that do not impact directly on the measurement

process and thus strongly influence what may otherwise be regarded as

the best practice approach to the job. Nevertheless, and regardless of

the specificity of the job; an important objective in a survey is to get

the best possible results. This is typically synonymous with the highest

attainable precision. For the highest precision, it is generally

required to minimize errors. To minimize errors, it is imperative that

instrumentation is in proper working order. To ensure that an instrument

is fully functional, it is essential to test and/or calibrate it.

Considerable efforts have been made concerning survey instrument

testing. In particular the ISO standard 17123 parts 1 through 8 have

been published[1]. Instrument manufacturers often quote these standards

when making reference to their instruments precision. Each of the ISO

17123 standards prescribes test procedures aimed at determining: first

if the instrument is functioning correctly; and second, qualifying its

precision and performance. These tests should be made on a regular basis

2. STANDARDS

Few people question that their banking card works at every money

machine in the world, but this confidence could not be possible without

standards. While driving we stop at hexagonal, not round or

square-shaped stop signs. These are just two of the thousands of

standards that impact on our everyday lives.

A standard is a rule or requirement that is determined by a consensus

opinion of users and that prescribes the accepted and (theoretically)

the best criteria for a product, process, test, or procedure. The

general benefits of a standard are safety, quality, interchangeability

of parts or systems, and consistency across international borders.

ISO (International Organization for Standardization) is a global

network that identifies what International Standards are required by

business, government and society, develops them in partnership with the

sectors that will put them to use, adopts them by transparent procedures

based on national input and delivers them to be implemented

worldwide.[2]

The GIS/Geomatics profession is concerned by several series of ISO

standards. There are the ISO 12858 series concerning ancillary devices

for geodetic instruments; the ISO 17123 series field procedures for

testing geodetic and surveying instruments; and the ISO 191XX (6709,

19104, 19111, 19116, 19127, 19132, 19133, 19134, 19145) family

concerning standardization in the field of digital geographic

information. They aim to establish a structured set of standards for

information concerning objects or phenomena that are directly or

indirectly associated with a location relative to the Earth. Of

particular interest is ISO 19111 - Spatial referencing by coordinates

(i.e. geodesy). The FIG is very actively involved in standardization. A

good review of the merits of standardization in the field of surveying

is available on the FIG web page dedicated to this subject (http://www.fig.net/standards_network/index.htm).[3]

Another important standard that concerns the GIS/Geomatics profession

is the ISO 9000 family of standards. The ISO 9000 standards represent an

international consensus on good management practices aimed at ensuring

that a business or organization consistently delivers products or

services that meet the customer's quality and regulatory requirements

while aiming to enhance customer satisfaction, and continual improvement

in performance. These best practices have been distilled into a set of

standardized requirements for a quality management system (ISO

9001:2000). [4] They are applicable regardless of what the organization

does its size, or whether it's in the private, or public sector.

3. BEST PRACTICE

Best practice in GNSS is a broad field. Nevertheless, there are

several commonly accepted generic guidelines that can be regarded as

best practice to achieve optimal measurement results. These guidelines

typically aim to minimise the errors associated with GNSS measurements.

Listed below are several well known and common GNSS errors that

degrade the accuracy of derived coordinates in surveying applications:

- Multi-path and Electrical Interference,

- Obstructions,

- Ionospheric and Tropospheric influences,

- Incorrect Integer Ambiguity,

- Dilution of Precision (DOP) and Satellite Availability (SA),

- Inappropriately long Baseline Length,

- Lack of network redundancy,

- Use of poor quality or degraded benchmark and/or datum

references,

- Malfunctioning equipment,

- Blunders and human errors due to ignorance and bad survey

practice.

It should be noted that errors are often more likely to occur or to

be exacerbated in RTK surveys because of the relatively short occupation

times used.

Best practice in GNSS strives to avoid or minimise errors while

supplying appropriately documented measurements. This is done by

providing (legally) traceable measurements using an (inter)nationally

recognised reference network. Furthermore, equipment should be correctly

functioning and field tested (ISO 17123 part 8). Finally, properly

trained personnel prepared to confront the multiplicity of field

situations will always make the difference between a good or bad survey.

Typically a survey should be connected into several (at least 3)

stations in the reference network. They should become part of the survey

and should be used to constrain it. The level of agreement between

measured and reference values must conform to the precision required for

the survey, the GNSS technique employed and the client accuracy

specifications. For example, if one metre accuracy is required using

differential GNSS, then the measured and reference values should agree

to within 1 metre.

The connections to reference stations should be documented, outlining

the GNSS technique and reduction process, least squares adjustments, and

a comparison/analysis of the derived values. Archiving of raw

observation data and results files is highly recommended.

4. INSTRUMENT TESTING AND CALIBRATION

One common sense rule in the ISO 9001:2000 standard (chapter 7.6)

concerns the control of monitoring and measuring devices. Specifically

it requires that whenever necessary to ensure valid results, measuring

equipment shall be calibrated or verified at specified intervals, or

prior to use, against measurement standards traceable to international

or national measurement standards; where no such standards exist, the

basis used for calibration or verification shall be recorded.[4]

Surveyors have traditionally been very concerned about

instrumentation, its functionality and performance. At one time

instrument testing was second nature. Today, however with modern survey

instruments and their associated complexity, there is a tendency, due to

among other things the rapidity and simplicity of the measurement

process, to assume the measurements are exempt of error.[6] This of

course is not true.

Each of the ISO 17123 standards prescribes measurement procedures

aimed at qualifying an instrument precision and performance. They also

serve to verify if the instrument is in correct operating condition.

These tests should be made on a regular basis. For example field tests

can be made: at regular six month intervals; before and after a series

of precision measurements; after a long period of inactivity; and after

transport.[6]

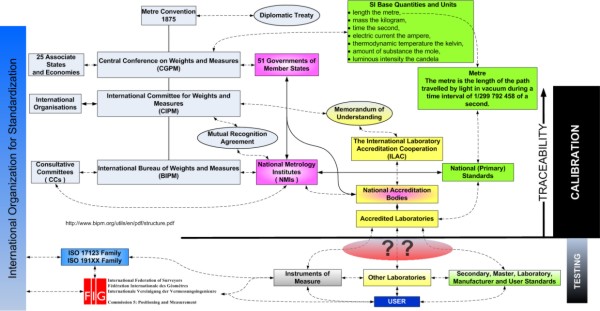

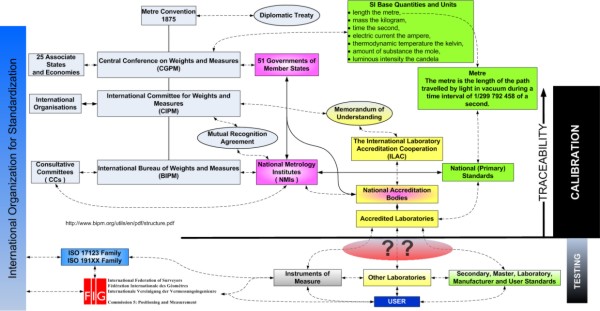

Instrument testing (ISO 17123) should not be confused with an

instrument calibration. Calibration links the instrument directly to

international standards (see Figure 1 below). Calibration is the act of

checking or adjusting by comparison with a standard or reference the

accuracy of a measuring instrument. A standard or reference is an

instrument or method that will measure more accurately and precisely the

desired quantity than the measuring instrument itself. For example a

laser interferometer measures more accurate distances (relative

displacements) than a total station Electronic Distance Meter (EDM).

Figure 1. Structure of the notion of traceability, calibration

and testing of survey instruments.

One of the pillars of instrument calibration is the notion of

traceability. Indeed traceability is at the root of all legal metrology

and measurement. Traceability is a method of ensuring that a measurement

(even with its uncertainties) is an accurate representation of what it

is trying to measure. With traceability, it is possible to demonstrate

an unbroken chain of comparisons that ends at a national metrology

institute (NMI). Figure 1 above illustrates the links through the CGPM,

CIPM and BIPM to the NMI’s and Accreditation authorities to the user and

his/her instrument. Note that traceability is not assured if an

instrument is not linked through an accredited laboratory to a national

standard.

At present there is no consensus on GNSS calibration. This is because

it is complex field and there are differing, valid points of view

concerning what exactly needs to be calibrated and how to go about doing

it. Examples of different approaches are: anechoic chambers, baselines,

field testing facilities and robots. (see for example [5])

5. ISO 17123 PART 8: GNSS FIELD MEASUREMENT SYSTEMS IN REAL TIME

KINEMATIC (RTK)

This standard specifies field procedures to be adopted when

determining and evaluating the precision (repeatability) of Global

Navigation Satellite System (GNSS) field measurement systems (this

includes GPS, GLONASS as well as the future systems like GALILEO) in

real-time kinematic (GNSS RTK) and their ancillary equipment when used

in building, surveying and industrial measurements. Primarily, these

tests are intended to be field verifications of the suitability of a

particular instrument for the required application at hand, and to

satisfy the requirements of other standards. They are not proposed as

tests for acceptance or performance evaluations that are more

comprehensive in nature.

The results of the test are influenced by several factors, such as

satellite configuration visible at the points, ionospheric and

tropospheric conditions, multipath environment around the points,

precision of the equipment, quality of the software running in the rover

equipment or in the system generating the data transmitted from the base

point.

The test field consists of a base point and two rover points. The

location of the rover points must be close to the area and in time to

the task concerned. The separation of two rover points is between 2 m

and 20 m. The horizontal distance and height difference between two

rover points are determined by methods with precision better than 3 mm

other than RTK. These values are considered as nominal values and are

used simply to ensure that the GNSS measurements are free of outliers.

The standard proposes two tests: the simplified and the full test

procedures. The simplified test procedure consists of a single series of

measurements and provides an estimate of whether the precision of the

equipment is within a specified allowable deviation.

The simplified test procedure is based on a limited number of

measurements so a significant standard deviation cannot be obtained and

no statistical tests are applied.

The full test procedure is used to determine the equipments best

achievable measure of precision. It comprises three series of

measurements and is intended to determine the experimental standard

deviation for a single position and height measurement.

It may be used to determine:

- the measure of the precision of equipment under given conditions

(including typical short and long term influences);

- the measure of the precision of equipment used in different

periods of time or under different conditions (multiple samples);

- the measure of the capability of comparison between different

precision of equipment achievable under similar conditions.

- Statistical tests are applied to the test results.

6. SUMMARY

This paper has aimed to review standards, calibration, testing and

best practice in GNSS. It is necessarily brief. Nevertheless, no one can

doubt the importance of standards and best practice in the modern world.

Surveyors are becoming more and more involved in the standardization

process. This is clearly underpinned by importance standards have taken

on in geomatics profession and the FIG today.

One important aspect of standards is the periodic testing and

calibration of survey instruments. The ISO standard 17123 Optics and

Optical Instruments - Field Procedures for Testing Geodetic and

Surveying Instruments is concerned with survey instrument testing. In

particular part 8 of this standard GNSS field measurement systems in

real time kinematic (RTK) outlines a commonly accepted method to be

adopted when determining and evaluating the precision (repeatability) of

Global Navigation Satellite System (GNSS) field measurement systems

(this includes GPS, GLONASS as well as the future systems like GALILEO)

in real-time kinematic (GNSS RTK) and their ancillary equipment when

used in building, surveying and industrial measurements.

REFERENCES

- ISO, ISO 17123 Optics and optical instruments - Field procedures

for testing geodetic and surveying instruments Parts 1 to 8.

2001-2007, ISO: Geneva Switzerland.

- ISO, ISO in brief International Standards for a sustainable

world, I.O.f. Standardization, Editor. 2005, International

Organization for Standardization.

- Greenway, I., FIG Guide on Standardisation. 2006, FIG Task Force

on Standards.

- ISO, Quality management systems — Requirements. 2000:

International Organization for Standardization.

- Wübbena G., S.M., Mader G., Czopek F. GPS Block II/IIA Satellite

Antenna Testing using the Automated Absolute Field Calibration with

Robot. in ION GNSS 2007. 2007. Fort Worth, Texas, USA.

- Staiger, R., Le Contrôle des Instruments Géodésiques. XYZ Revue

de l'Association Français de Topographie, 2004. 99(2): p. 39-46.

BIOGRAPHICAL NOTES

David Martin is head of the ESRF Alignment and Geodesy Group.

He holds an MSc in Surveying from the Department of Geomatic

Engineering, University College London. He is the chair of FIG Working

Group 5.1 Standards, Quality Assurance and Calibration. He has published

a number of papers concerning accelerator alignment, survey instrument

calibration and hydrostatic levelling systems.

MORE TO READ

Powerpoint presentation at the FIG Working Week 2008 in Stockholm,

Sweden, June 2008:

http://www.fig.net/pub/fig2008/ppt/ts04c/ts04c_01_martin_ppt_2872.pdf

CONTACTS

David Martin

European Synchrotron Radiation Facility (ESRF)

6, rue Jules Horowitz

BP 220

F-38043 Grenoble Cedex 09

FRANCE

Tel. +33 (0)4 76 88 22 45

Fax +33 (0)4 76 88 23 13

Email: martin@esrf.fr

Web site: http://www.esrf.eu

|